Managing logistics without clear performance data to guide your business is like driving with a blindfold. You make decisions without knowing what’s really working. That’s where a Transport Management System (TMS) comes in handy.

By tracking key logistics metrics, businesses can easily identify inefficiencies, reduce costs, and put measures in place to improve delivery performance – with data-backed decisions.

In short, TMS analytics can help your business get the real-time insights you need to make your existing processes work better for you.

But before we dive into all that, let’s first establish what a TMS, or transport management system, actually is.

What is a Transportation Management System (TMS)?

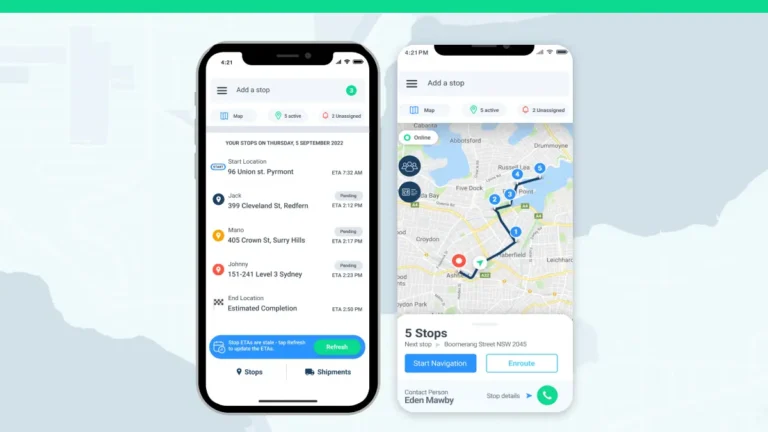

A TMS is software that helps businesses manage and optimize transportation logistics by tracking shipments, analyzing costs, and improving operational efficiency.

That’s the technical answer.

The simpler explanation: It’s software for companies that want to use data and analytics to make better decisions. These are the kinds of decisions that reduce expenses, increase profit, and keep everyone happy.

Because without data-driven insights, businesses risk overspending and are bogged down by delays. All of that can lead to unhappy customers, which means a loss of business opportunities.

Why tracking logistics metrics matters

As we’ve established, data is the backbone of efficient operations. Without accurate, real-time insights, your business could struggle with unexpected costs.

Drivers could be wasting time and resources by figuring out the best routes manually.

Office and warehouse staff could be overwhelmed by the sheer amount of paperwork and follow-up calls to customers when deliveries are delayed.

But if you track logistics metrics with a transport management system, you’d be able to spot trends, adjust accordingly (before the problem escalates), and just overall improve your company’s performance.

10 essential TMS metrics to track

So, with that said, let’s take a look at the top 10 metrics you need to track with a TMS to optimize your logistics strategy.

1. Transport costs

Shipping and expenses can add up super fast. Without proper tracking, it’s impossible to know where you are overspending and where you should be cutting down.

But a TMS will be able to break down the costs by carrier, route, and shipment type. This gives your business clear visibility into logistics expenses.

With this data, you can identify cost-saving opportunities, for example, to:

- optimize routes,

- consolidate shipments,

- negotiate better carrier rates.

2. On-time delivery performance

Customers want fast deliveries, and they want those deliveries on-time. If your shipments or stops are delayed all the time, customer satisfaction takes a hit and they might just take their money elsewhere.

And if they don’t switch to another supplier, the experience could end up hurting your business. In 2022, professor of business administration Prashanth Ravula studied customer sentiment towards delivery performance.

He found that customers assign significantly lower ratings to orders delivered late compared to those delivered on time. Apart from just losing a customer’s support, you’d also risk your brand reputation with delayed deliveries.

3. Carrier performance

Not all carriers are made equal or deliver the same level of service. A TMS tracks key carrier metrics such as on-time performance, damage rates, and compliance with service-level agreements (SLAs).

With this data, you can compare carrier performance, renegotiate contracts, and make data-driven decisions about which carriers to use.

Think of it like this: poor-performing carriers cost businesses money and create inefficiencies, but using a TMS can eliminate that problem.

4. Fuel consumption

Fuel is one of the biggest costs in logistics. Without proper tracking, your business will bleed money and you might not even realize how much you are losing because it is so hard to quantify.

A TMS overcomes this hurdle by monitoring fuel usage across different routes, vehicles, and drivers. This way, you can easily spot the type of inefficiencies that drive up costs, i.e., inefficient routes, harsh braking, or overdue maintenance.

And beyond just finding the faults for you, a transport management system can optimize those routes, and give you the data to adjust driver behavior and maintenance schedules.

Remember: Smarter fuel management equals better profitability and sustainability.

5. Load efficiency

Are you sending out half-full trucks? That’s money down the drain.

A TMS can track load efficiency too, so businesses are able to maximize vehicle capacity and reduce the number of unnecessary trips.

Better load management means lower costs and increased profits.

6. Freight audit and payment accuracy

Incorrect freight invoices can cost businesses thousands of dollars in overpayments.

With a TMS, you can automate the freight audit process to flag errors, inconsistencies, and incorrect charges. Before payments are even made!

Doing this will ensure you only pay what you actually owe, So, over time, automated audits prevent hidden losses and streamline expense tracking.

7. Transit time

Transit delays slow down supply chains and frustrate customers.

A transport management system tracks actual transit times across different carriers and routes. This allows businesses to identify slow routes, so they can adjust schedules and improve overall efficiency.

By using historical data to refine logistics strategies, your company can reduce unnecessary delays and speed up order fulfillment.

8. Order accuracy

Delivering the wrong product or incorrect quantities creates costly returns and unhappy customers. But with a TMS, you can track order accuracy rates, helping businesses identify patterns of fulfillment errors.

With TMS-driven analytics, companies can pinpoint where mistakes happen (whether in order picking, packing, or labeling) and implement process improvements.

Fewer errors mean fewer complaints and higher customer trust.

9. Customer satisfaction

At the end of the day, logistics success is measured by customer happiness. A TMS tracks customer satisfaction metrics.

Think: delivery speed, order accuracy, and response times to inquiries.

By analyzing these insights, you can identify pain points, fix recurring issues before they escalate, and improve the overall customer experience.

Remember: Satisfied customers = repeat business and better brand loyalty.

10. Carbon footprint

Last but by no means least, the sustainability aspect! It’s no longer an optional part of business operations; it’s an expectation.

A transport management system can track emissions, fuel efficiency, and eco-friendly logistics practices. This data will help your business reduce its environmental impact.

By monitoring and optimizing routes, consolidating shipments, and reducing idle time, you can lower carbon emissions while also saving money.

After all, eco-friendly logistics is smart business for a reason!

Final thoughts on using a transport management system

Without the right data, logistics inefficiencies go unnoticed. This means higher costs, late deliveries, and operational headaches.

But a TMS can give you critical logistics metrics, right at your fingertips. This will help you with data-driven decision-making, cost control, and performance improvements.

By tracking fuel consumption, order accuracy, transit times, and customer satisfaction, your business can retain that competitive edge.

The companies that leverage TMS-driven data today will lead the way in efficiency, cost savings, and long-term success.

Will your company be one of them?

About the author

Cheryl has contributed to various international publications, with a fervor for data and technology. She explores the intersection of emerging tech trends with logistics, focusing on how digital innovations are reshaping industries on a global scale. When she's not dissecting the latest developments in AI-driven innovation and digital solutions, Cheryl can be found gaming, kickboxing, or navigating the novel niches of consumer gadgetry.