The prosperity of a business is heavily reliant on having an effective inbound and outbound logistics strategy.

Inbound & outbound logistics operations influence manufacturing, profitability and customer satisfaction.

Here is a complete guide as to what inbound and outbound logistics are, inbound and outbound logistics process as well as ways in which you can optimise both.

Inbound & outbound logistics have their own set of challenges to overcome, such as inventory and transportation costs, shifts in supply and demand, growth in consumer demand and that’s just to name a few.

Before we get straight into the details, the following paragraphs will highlight what is logistics and then go into depth about inbound and outbound logistics.

What Is Logistics?

The term logistics refers to the process of managing, storing and transporting goods and raw materials.

Unreliable logistics within an operation can negatively impact its foundation and the overall process of transportation.

Here are a few ways poor logistics can influence your business:

- Lack of customer trust

- Negative impact on business reputation

- Production delays

- Shipping delays

- Client relationship deterioration

- Higher costs

That’s why having a management system that (no pun intended) delivers can help enhance profits and customer service. Keeping your business in check at all times!

The goal of logistics is to have the accurate quantity of resources available and transport them to the right location without issue.

What Is The Difference Between Logistics And Transport?

Because logistics involves transportation then it must be the same, right?

Actually, the logistics industry is exceedingly larger than the transportation industry, implying a broader spectrum that not only delivers products but includes handling, packaging, inventory and storage.

What is Transportation

Transportation is the movement of goods to their destination

What is Logistics

Logistics involves sourcing, producing, warehousing and distributing an accurate quantity of materials to their destination.

5 Types Of Logistics

Third party logistics (3PL Logistics)

Third party logistics is the outsourcing of ecommerce logistics to a third party organisation. This can include inventory management, warehousing, fulfilment and distribution.

Third party logistics arranges inbound and outbound shipments for their customers.

A customer’s business hires a third party provider to grant access to space for their large quantity of products.

Warehouse team members will then manage these items and place them in the inventory.

Fourth party logistics (4PL)

Fourth party logistics is when manufacturers outsource all of the operation and supervision of the supply chain and logistics to a singular external provider.

The responsibilities this partner must manage include inspecting, building, running and weighing solutions for customers.

They control and manage the supply chain by organising warehouses, shipping companies, products and agents.

Because of their extensive network and connections 4PL gives businesses the ability to focus just on the product without the difficulty of the supply chain.

Inbound logistics

inbound logistics refers the method in which raw materials are sourced and transported into the company. This can include fulfilment centres, warehouses and retail stores.

An example of inbound logistics includes receiving inventory into a warehouse straight from the manufacturer where it must be unloaded, checked and placed into the warehouse management system.

Outbound logistics

Outbound logistics is the method in which finished goods are transported to their destination. outbound logistics focuses more on the demand part of the supply-demand concept.

Outbound logistics includes warehousing and storing a certain number of goods to meet customer demand. It also deals with outgoing completed products and transporting them to their allocated destination.

Reverse Logistics

The term ”reverse logistics” refers to the process in which goods move from customers back to the wholesalers or manufacturers. It can involve e-commerce and retail returns as well as repair and recycle. And the goods can be resold or permanently discarded.

The reverse logistics process involves managing returns and purchasing leftover products.

For example, the reverse logistics procedure in the beverage sector makes use of empty tap containers.

Companies that produce beverages want to reuse their containers to recoup their original cost. This requires organising transportation, managing shipping loads, and container cleaning.

What Is Inbound Logistics?

Inbound logistics is the method in which materials are transported into the company. This can include fulfilment centres, warehouses and retail stores.

An example of inbound logistics involves receiving inventory into a warehouse straight from the manufacturer where it must be unloaded, checked and placed into the warehouse management system.

Inbound logistics process

Below will highlight the following inbound logistics processes:

Procurement

Inbound logistics works by firstly procuring suppliers. A way this is achieved includes identifying and analysing possible suppliers, sorting quotes and reaching an agreement with suppliers.

Purchase & Transportation

What follows is the purchase of resources and items the business requires, ensuring the accurate amount is delivered on time. The next step is deciding the mode of transportation. This includes moving materials by aeroplane, truck or train.

Handling

Businesses must now handle resources that have just been received and organise them into assigned locations.

Management

These materials should then be managed prior to being transported to fulfilment centres. Items should be placed in an environment that is suitable to their requirements.

Expedition & Distribution

They are then expedited to the allocated facility or distributed to their destination within the business.

Businesses can check on arriving orders, having access to documents and its location for peace of mind.

Reverse Logistics

However, not everything goes to plan. This is where reverse logistics comes in, where goods are brought back from customers as a result of damages, returns, delivery issues and so on.

The way in which a business tackles inbound logistics can differ depending on the industry, relationship between buyers and sellers, as well as the type of incoming material.

What Is Inbound Supply Chain Management?

Inbound logistics heavily influences the manufacturing strategies of an organisation and if executed properly, will reduce waste of resources and production costs.

Managing inbound logistics expenses effectively can also result in better efficiency when it comes to costs within the supply chain.

Inbound logistics impacts the final result of an item sold to customers, which is why an efficient system is required. That way customers aren’t disappointed with the quality of a product they’ve received.

Should your inbound logistics operations be running smoothly, you can arrange for lowered carrier costs and better management of your inventory.

Because this is the first step in the supply chain, should things go wrong it can negatively impact other stages. This can halt production and cause significant delays.

There are several advantages that come with an effectively functioning inbound logistics. These include:

- Can identify early issues within supply chain

- Predict cost of materials

- Enhanced inventory management

- Great vendor relationships

- Higher quality of products

- Increased orders

- Improved customer satisfaction

- Reduced wasted materials

- Reduced total overhead

How Do You Manage Inbound Transportation?

Establish transparency

Tracking transportation helps minimise the amount of time consumers spend confirming shipments. Additionally, it assists in observing the performance of carriers. That way you can identify any issues throughout the journey and file for service failures.

Negotiate lower rates

Considering businesses everywhere are looking to spare expenses wherever they can, negotiating with vendors for a lower price can mean all the difference.

Purchasing a higher quantity of goods can assist you in receiving transportation discounts. Most of the time, having less providers allows you to leverage more.

Inspect inbound delivery procedure

Inspect your vendors, as well as where they are shipping from. You should then choose the route being taken, mode of transportation and the type of goods being shipped.

Highlight the extent of transparency your organisation requires when it comes to shipments and transit times.

You can easily notice poor carrier service if their rates are exceedingly high, along with ineffective routing.

Use a core carrier program

To avoid confusion in regards to the several carriers approaching your dock, a core carrier program will enable you to recognise a carrier’s pickup coverage, time of transit and facility locations.

How Can Inbound Logistics Cost Be Reduced?

Route planning

Devising personalised routing guides and integrating a vendor compliance program is a great starting point to not only managing shipping costs, but reducing them too.

Having an automated route planning guide will enable you to view crucial information such as admissible types of transportation, updates, receiving hours and so on.

If a shipper doesn’t act in accordance with typical operating policies, then the vendor compliance program will require payment or action from the organisation responsible.

Leverage technology

Choosing to manually manage shipments can reduce transparency and efficiency because of lags in updates.

Having a transportation management software can increase shipper visibility and tracking transit.

Shippers can also determine if a vendor has allocated an inaccurate route or pricey mode of transportation.

Work with logistics partner

With a reliable logistics partner, shippers can improve the management of their supply chains, creating a more proactive system

It pays to have guidance from an industry professional, so with a logistics partner by your side, you’ll have the means to save time and resources.

What Is Outbound Logistics?

Outbound logistics is the method in which finished goods are transported to their destination. This type of logistics is focused more on the demand part of the supply-demand concept.

Whilst both inbound and outbound logistics involve the transportation of goods, the difference is that inbound refers to all processes associated with acquiring materials from suppliers and manufacturers. Whereas outbound is the transport of goods to customers.

Below will highlight the following outbound logistics activities:

Customer order

What kicks off outbound logistics obviously begins with the purchase of goods. Customers will purchase a product from an operations’s facility.

Confirmation

When the warehouse confirms the order of goods, team members will assign the most suitable inventory.

Packaging

Team members will then package the goods so they are ready for transportation, transferring them to the loading dock.

Transportation

The mode of transportation will vary as determined by the type of items. An example includes items that need to be moved in temperature controlled carriers to avoid spoiling.

Delivery

The customer’s order must arrive on time with the accurate type and amount of goods. Outbound logistics takes care of any delivery issues like lost or damaged items within transit.

Benefits Of Inbound Logistics

Here are the following benefits that can be experienced should inbound logistics be run efficiently.

- Accurate delivery times

- Lower shipping and receiving costs

- Strong vendor relationships

- Anticipate issues within supply chain

- High quality of product

- Strong potential for sales success

Benefits Of Outbound Logistics

Outbound logistics enable businesses to delight their customers. If outbound logistics are well run, there are a range of benefits that can be experienced.

This can include:

- Less cancellations and returns

- Faster deliveries

- Accurate delivery times

- Reduced damage of product in transit

- Less delivery failures

- Strong business reputation

- High customer satisfaction

Outbound logistics processes

Inventory Management

Inventory management regulates how to source goods from suppliers so you have the right quantity of products to sell to customers.

Although managing inventory is the final stage of inbound logistics, it’s the first phase for outbound logistics.

The main goal is to secure the right amount of inventory for customers. That way you don’t run the risk of having too much or not enough. It’s all about balance!

Warehousing & Storage

This process influences the way in which your products are stored and how they’ll be prepared for delivery.

Storing is a great way to maintain a certain number of goods, given it’s nearly impossible to accurately forecast demand.

Transportation

This is where goods are moved across the first and last mile of delivery. The mode of transportation is dependent on the type of shipping you offer and what items are being delivered.

Perishable goods typically need to be transported in a temperature controlled carrier to avoid spoiling.

Last-mile delivery

Last mile delivery is the final stage of the delivery process where goods residing in a transportation hub are then shipped directly to the customer’s chosen destination.

What Is the Difference Between Inbound and Outbound Logistics?

Inbound and outbound logistics are the most common practices to advance goods across the supply chain.

Inbound and outbound. In and out. Pretty simple right?

Inbound logistics focuses on bringing resources into the business and on the other hand, outbound logistics moves goods to the customer.

How Do You Optimise Inbound And Outbound Logistics?

Lower inventory costs

With the growth of your operation, you can expect an increase in inventory expenses. Aligning your inventory with the demand being experienced can help optimise your inbound and outbound logistics.

Building relationships both ways–suppliers and last mile carriers

Having a strong relationship with suppliers and last mile carriers allows your operation to minimise costs, cut back lead and enhance your overall logistics experience.

This can be achieved by increasing how much you are ordering over a period of time, being respectful of their services and paying them on time! It’s that simple.

Route optimisation

Route optimisation is a software that creates time-effective routes, taking into account the number of stops, availability of drivers, traffic and location.

This solution reduces the amount of time drivers spend on the road resulting in faster deliveries, as well as unnecessary fuel costs.

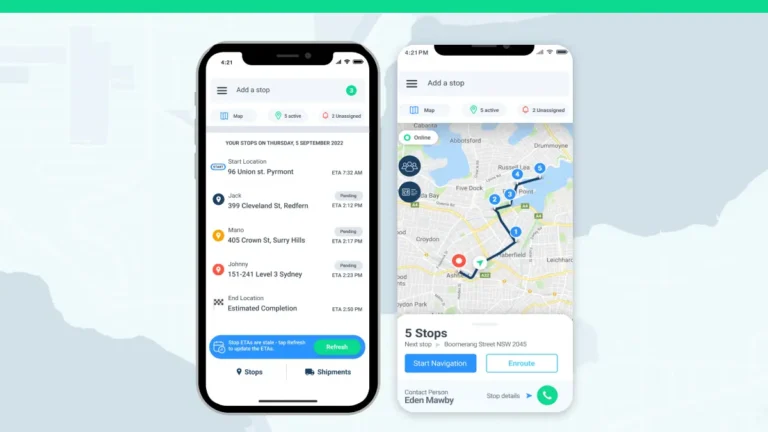

Locate2u can optimise your routes and allow you to add in last minute stops to increase your business’ overall efficiency. No more pen and paper just enhanced productivity.

Warehouse management system OR transportation management system

Finding the right software can assist in optimising both inbound and outbound logistics.

A warehouse management system can manage your inventory, streamline your bookings and provide updates on their status.

A transportation management system is a logistics solution that employs technology to assist businesses when it comes to planning, executing and optimising the movement of goods

Challenges Of Inbound Logistics

Inefficiencies

Shipping inefficiencies are one of the biggest challenges of inbound logistics.

This includes extended delays, limited driver availability, poor weather conditions, changes in the route being taken etc.

Such inefficiencies can impact the customer experience, leading to negative reviews published online for others to see, with an unlikelihood of future purchases.

Costs

Currently there has been an unprecedented increase in fuel prices, contributing to the surge of inbound logistics costs.

Delays and excessive vehicle idling also add to transportation costs, making it imperative for businesses to find solutions to minimise expenses.

Shift in supply and demand

Supply and demand is an example of nothing being set in stone. Global events like the pandemic, seasonal peaks and economic factors are what see the shift in demand.

Without demand forecasting, it can be difficult for businesses to anticipate how much supply to maintain in their inventory.

Integrating technology that analyses customer behaviour and demand patterns can assist with this challenge.

Processing returns

Returns are often not a high priority for some operations. This can result in sales being lost should stock not be returned into the inventory accurately.

Incorrect inventory counts and poor customer service only add to this challenge.

Challenges Of Outbound Logistics

Coordination of outbound operations

Outbound logistics team members should constantly be monitoring production, storage and distribution. Keeping track of the movement of goods isn’t easy.

If the quantity of products increases to meet demand, then more warehouses and shipping must be established.

Supply chain efficiencies rely on a productive outbound logistics network. Completed goods require a number of movements throughout the supply chain up until they reach the end customer.

Effective e-commerce logistics processes means businesses will find it difficult to source products and have items delivered to the final destination.

Costs

Businesses ensuring their inventory is holding enough to accommodate customer demand, without holding too much is a tricky balance.

Should too much stock be held in the inventory it will take up space that could be used for other items.

If items are perishable, ordering too much can lead to a waste in expenses.

Growing consumer demands

Keeping customers happy isn’t easy. They expect their item to be delivered on time, without issue. Considering same-day delivery can now be carried out, more customers are wanting this service.

Some businesses may struggle to give their customers this experience and should there be delays, missing or misplaced deliveries, they risk their reputation in the market.

Advantages Of Optimising Inbound And Outbound Logistics

Accurate ETAs

Having a route optimisation solution like Locate2u will build the most time-efficient routes for your fleet, allowing you to give accurate ETAs to customers.

That way, they don’t have to anticipate when their item will arrive or rely on a large time window between 7am to 7pm.

Faster deliveries

The faster the better and that couldn’t be truer when it comes to deliveries. By optimising inbound and outbound logistics, the overall process from sourcing, distribution to destination can be made faster.

Better management

Having a warehouse management system can assist in managing your inventory, automating bookings, providing real-time tracking and status updates.

It gives peace of mind for business owners and those in charge of these operations that everything is working efficiently to deliver the best possible outcome for the customers.

Happy customers

Keeping customers happy and giving them great service is what every operation hopes to achieve.

By optimising inbound and outbound logistics, your customer can experience faster deliveries and access improved visibility. This allows them to anticipate when their item will arrive.

What Is The Importance Of Inbound And Outbound Logistics?

Inbound and outbound logistics are significant parts of an organisation’s supply chain as they impact profits, manufacturing and customer satisfaction.

An efficient inbound logistics strategy will see the production of higher quality goods, reduction in costs and enhanced profitability.

Additionally, having an accurate outbound logistics structure will provide transparency of distribution, helping companies give their customers a better delivery experience with live tracking.

Is Inbound Or Outbound Logistics More Important?

You can’t really determine whether inbound logistics is more important than outbound logistics and vice versa.

Inbound logistics focuses on sourcing, managing and distributing materials, whilst outbound is responsible for moving products to customers.

‘What goes in must come out’ That can be said about inbound and outbound logistics. They are both equally important roles!

Manage Logistics With Locate2u

Locate2u is a delivery management software that can help your organisation reduce operational costs, time spent on the road and improve customer satisfaction.

Locate2u offers route optimisation, booking management, real-time tracking and updates, so you have full visibility of the process.

Automate your deliveries with Locate2u today! Click here for a demo

Inbound logistics FAQs

What is inbound logistics?

Inbound logistics refers the method in which raw materials are sourced and transported into the company. This can include fulfilment centres, warehouses and retail stores.

What is inbound logistics example?

An example of inbound logistics includes receiving inventory into a warehouse straight from the manufacturer where it must be unloaded, checked and placed into the warehouse management system.

What are key components in inbound logistics?

- Procurement

- Purchase & transportation

- Handling

- Management

- Expedition & distribution

- Reverse logistics

Outbound logistics FAQs

What is outbound logistics?

Outbound logistics is the method in which finished goods are transported to their destination. This type of logistics is focused more on the demand part of the supply-demand concept.

What is outbound logistics example?

An outbound logistics example includes an order that comes into a retailer and is fulfilled from a distribution center. A delivery driver will pick up the order from the distribution center (or other location) and deliver it to the end customer.

What are key components in outbound logistics?

- Warehousing and storage

- Inventory management

- Transportation

- Last-mile delivery